ACK Gioia

Elizabeth Hitchcock, a native Neapolitan, met her husband Dave, a native Cape Codder, 33 years ago while attending college in Rome. Relatively soon after, Dave needed to return to Orleans, where he and his father made their living fishing and keeping lobster traps, and Elizabeth came with him. Wanting to expand their opportunities, the couple washed ashore on Nantucket as newlyweds in the fall of 1988.

In 2011, Elizabeth embraced cheesemaking, “Because I could not find a ball of mozzarella worthy of eating. I started ‘pulling’ for fun, family and friends,” she said. ACK Gioia was born (ACK is the Nantucket airport code and gioia is joy in Italian) and has brought joy to so many with its homemade mozzarella, stracciatella and burrata.

Cheesemaking is a family affair. Daughter Alex, Elizabeth’s “right hand,” who usually helps make cheese, has been setting up their commercial kitchen in Brewster. Dave is the “master shredder” and inventor of implements to improve the process.

With Alex on the Cape, Elizabeth needed another cheesemaker, and, after some trial and error, hired a young man who became adept at keeping the mixtures pliable and the size of the output consistent. This has allowed her to realize her dream of marketing on the Cape. “I was finally ready to go larger and have been partnering with the Brewster Farmers’ Market for their curbside pickup,” she said. Her burrata and stracciatella cheeses are already on the menu at Chatham Bars Inn.

The ingredients for the cheese are five-pound blocks of curd (milk solids separated from liquid cow’s milk), kosher salt and a bath of 212-degree water. Elizabeth buys her curd from a Narragansett farm that is as local as she has been able to find. To create the three cheeses — mozzarella, stracciatella and burrata — there are several steps.

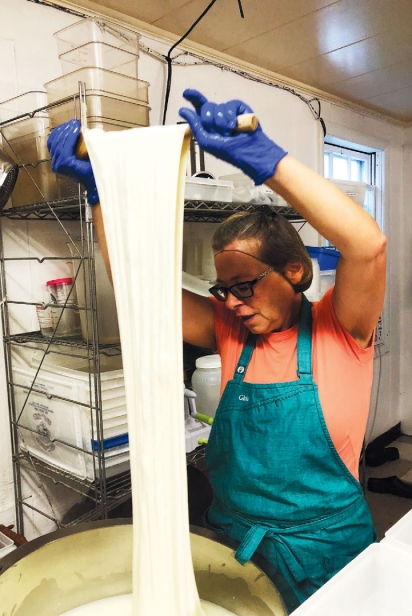

First, the mozzarella. The curd is sliced, salt is added, and the mixture is lowered into the hot water bath. Dave designed a double-jacketed stainless-steel vat that regulates the temperature and acts like a double boiler. The curd gets soft and sinks. As it does, some of its serum, a yellow fatty liquid, is released. Elizabeth is mindful of keeping in as much fat as possible. She stirs carefully with a wooden paddle and gently stretches and folds the mixture on a wooden dowel — a bit like pulling taffy — until the texture is light and airy. This pasta filata technique gives the cheese its fibrous structure; too much stretching causes it to become rubbery string cheese. She forms three-ounce balls for some customer requests, and eight-ounce balls for restaurants that prefer to serve slices. The mozzarella balls are placed in an ice water bath to cool them down. The milky substance that is left after the mozzarella and burrata have been made is great for making focaccia, which Elizabeth makes at home when she has time.

Meanwhile, using a shredding box he crafted, Dave makes the stracciatella by shredding a curd block to combine with a touch of salt and room-temperature heavy cream. The shreds sit and meld with the cream to form stracciatella, or curds and whey.

The third cheese, burrata, is the most labor intensive of the cheeses because the two others must be made first. The stracciatella is then wrapped inside the mozzarella to make the burrata. Dave joked, “After the first time Elizabeth made burrata she said, ‘I’m not making burrata. It’s way too labor intensive!’ And now she loves making it.” Elizabeth agreed, “It’s very calming and relaxing for me now,” she said in her soft accent.

The pair recommend serving the cheeses at room temperature, and they really should never be refrigerated unless you can’t eat them in a day or two. The word burro in Italian means butter, and the burrata is like butter if eaten in that timeframe.

The chef at Nantucket’s historic Jared Coffin House had a prep kitchen that was underused, and that is where the ACK Gioia magic happens. Elizabeth makes cheese on Wednesdays from 3:30 a.m. until 9 a.m. when things are quiet and she can focus. When her concentration is on target, she can make 100 pieces in an hour. On a summer day she will make 360 pieces and 30-40 pounds of stracciatella. And after that, she goes to her day job as a banker!

At a recent American Cheese Society blind taste competition with over 1700 entries from the United States and Canada, ACK Gioia’s burrata scored a 93 out of 100, and the stracciatella scored 94.5. Cheeses are scored on appearance, aroma, texture and flavor attributes and deficiencies.

The shop on Underpass Road in Brewster is set to open in late 2020 and will feature retail sales, cheesemaking classes, and large windows so customers can see the cheese being made. Cheesemaking classes will also be offered, with the first class already fully enrolled.

302 Underpass Road, Brewster (set to open late 2020)

Instagram: @ackgioia

(508) 325-5917