Do You Know the Mushroom Man?

Ruts and bumps force the car’s abandonment roadside. Striding through the forest, a nail through a mangled sign skewers a shaggy pine’s bark. Its edict, NO TRESPASSING, is rusted, the original color long gone. Dappled sunlight takes turns flickering with shadows. Past an empty tiny cabin and the shells of once-active greenhouses, a wide field opens up, cluttered with mechanical debris. A massive shrink-wrapped structure looms, metal supports pushing outward like ribs against its stark white skin. “Uli?”

“Oh, you came in that way,” a voice calls out as a doublewide garage door rolls up revealing wheat-colored work boots, worn trousers and finally, a young man’s tanned face. This is Uli Winslow, founder of Cape Coastal Products, a two-year-old mushroom cultivating operation. His venture already has a new name. One that arrived quite unsolicited. Winslow grins broadly, “‘Uli’s Mushrooms’ just stuck.”

Once inside the cavernous space, one can see it’s going to be not unlike poking around Willy Wonka’s chocolate factory. The color palette is of wood and metal tones, with the antioxidant cocoa elixirs and pastel sugary sweets replaced by ingredients that will help the mushrooms grow — quite magically, if you will.

Winslow explains that he’s beginning this indoor tour at the final phase of the growing process because seeing the end helps a person understand the steps along the way. In this facility he raises two of the three types of mushrooms he’s known for: the oyster and lion’s mane. Both were selected for their ability to grow year-round, as well as for their health benefits and taste. Nutritionally, mushrooms are a great source of vitamin D, with many varieties continuing to accumulate it after harvest as long as they are exposed to sunlight.

Winslow heads towards a boxlike structure, its exterior walls covered in a silver insulating material, noting that he just built the approximately 200-square foot space last weekend. He props opens a door and steps inside, “This is the fruiting room.”

All four walls have horizontal rows of open racks made of thin PVC piping. These supports will cradle block-like bags of inoculated growing substrate during the final growth push of these mushrooms. They will spend an average of eight to ten days in this room until maturity. Deceptively simple, upon closer inspection, several factors contribute to the eventual success of the grow. Winslow must maintain a high humidity level of 60%, supply heat in the winter, provide skylights so the mushrooms have access to natural sunlight, and orchestrate good air flow. He estimates his setup accomplishes a complete air exchange every five minutes through a wall ventilation system.

Leaving the fruiting room, we pause by a large well-worn wood-burning boiler surrounded by rows of fire bricks, the sort used inside a kiln. “This was Julie Winslow’s stove, and now this winter I’ll pipe the steam from it back over to that fruiting room for heat. I’ll be able to get the steam to about 160 degrees,” says Winslow, “which will work well.”

Julie Winslow, one of Uli’s parents, passed in 2011. A cornerstone of the Cape community, she lent an outstretched hand to many, and often helped residents with home repairs. Frequently vending produce and shiitake mushroom logs at the Orleans Farmers’ Market, Julie provided chimineas to warm sellers and buyers alike on the market’s coldest days. “It’s nice to have her stove here, and I’ll be using it soon,” says Winslow, touching its door. “She was really so ahead of her time, practicing aquaculture and inoculating logs for shiitake cultivation long before both practices became popular here. A visit to Japan years ago first fueled her curiosity for so many things. She brought home a small plastic bag of mushroom spawn from that trip.”

Uli, like Julie, chooses to follow an unconventional path. Opting out of traditional education after high school, he went straight to work growing produce with farmer David DeWitt and doing odd jobs for four years. For the past two years, he has worked on this site that once housed the Rockspray Nursery, a one-time popular source for heath and heather plants on Cape Cod with an extensive network of sales nationwide.

Now at the opposite end of this expansive space, we step up to a little nook, windowless and dark. A well-used metal drum rests here, in a thick insulating wrapper. Inside, Uli can place about 100 packages of the growing substrate at once. For 24 hours, a heating element within the drum effectively pasteurizes the contents with 200-degree steam, ensuring they are contaminant free.

Next to this area we enter a tiny room known as “the lab.” Well-lit and tidy, it’s where Winslow packages the loose bulk substrate before it gets steamed. Uli creates the material from a mixture of sawdust (processed without petroleum products,) and soybean hulls. He uses organic methods and chooses his raw goods carefully. “I have a direct relationship with my customers,” says Winslow, “and they know this.” He measures and blends his grow mixture and packs it into plastic bags which are then heat sealed.

Once the bags of substrate have cooled for two days after pasteurization, they’re ready to be injected with active spawn. After injection, each bag is fixed with a perforated patch to allow some air flow. Mushrooms reproduce naturally when spores are released from their undersides through their gills. Yet conditions need to be absolutely ideal for an x-spore and a y-spore to land in close proximity to result in active spawn.

Filled bags move on to the next space, the incubation room. Winslow can stack about 500 bags onto wooden gridded shelves that were also once Julie’s. As the active spawn within each bag matures, they decompose the substrate. The room has a vaguely sweet, slightly yeasty scent. “This process actually creates heat,” says Winslow, making it possible for him to maintain this room at a comfortable temperature in all but the worst winter weather. After two weeks of incubating, the bags enter their final step before harvest in the fruiting room, our first stop on the tour.

Winslow places the bags floor to ceiling in vertical columns from left to right across each wall. Each day, he adds a new column (or two depending on the yield he requires) to the right of the previous column. Eight days in, he can usually harvest the mushrooms in the first column, and then harvest one column a day moving left to right until an area is empty. “Look, you can see when the caps start to slightly curve upward,” says Winslow, “they’re ready.” Harvesting is simply breaking off a large section of the mature mushrooms. Winslow tries to do it as close to market as possible. Sometimes even he is surprised at how much growth is achieved overnight.

Leaving the indoor operation, we explore the grow area for the third mushroom Winslow raises: the shiitake variety, which is usually available from spring through November. Sheets of dark tattered shade-cloth hang from pine boughs. Underneath rest the logs, two to three feet long, placed in precise stacks. At first glance it’s a giant stash of firewood.

Here again, the layout reflects the thoughtful approach Winslow relies on to ensure quality production from each log as well as continuity of harvest. Three to four individual logs are placed in the same direction, with several inches open between each one unlike a tightly packed woodpile. This provides air circulation and space for the mushrooms to grow. The squared-off stacks rise vertically with each layer of logs crisscrossing the previous one, like living Jenga columns in the forest.

“How many?”

“I have 2000 inoculated logs right now,” he says, pointing to more across the dirt road. As one steps nearer and nearer, some shiitakes finally come into focus, particularly in one area of the stacks. It’s a reflection of his well-managed plan for a staggered harvest. These brown mushrooms are so well camouflaged they are scarcely visible. Their beauty beguiles, with shades of taupe, tan, white and brown hidden against the barks’ patterns. Plus, like tiny clumps of snow that never melted, here and there mini-marshmallow sized rounds dot the logs.

Winslow explains, “I use only oak and maple logs with a diameter of four to twelve inches, obtained from friends and landscapers, and sometimes by running ads. December to April is the best time to cut when these trees are dormant so the natural sugars within are preserved. Pine is too acidic and contains some inedible compounds. Next, I drill a pattern of holes into each log, filling each hole with mushroom spawn using an inoculation gun created for the purpose. It’s actually like a big syringe. Finally, I seal the openings with either a droplet of wax, or a tiny piece of Styrofoam to hold in the moisture, and the log joins the stacks in the woods.”

The record keeping begins. Winslow says, “A successfully inoculated log will fruit naturally in about 8 months. Following the first harvest, the log needs about 2 months to rejuvenate, allowing the natural decomposition process within it to occur, making more compounds available to nourish the mushroom colony growing inside.” After 2 months, he activates the log for growth by a 24-hour soak in well water (free of chlorine and other additives). He can wiggle about 35-40 logs into each of several huge plastic tubs he has for the purpose and, a day later, restacks the logs in formation.

Shiitakes will again appear on a log’s surface, growing from the initial inoculation of spawn that has now fully colonized the interior, reaching maturity in about a month. Harvested like the other varieties, Winslow simply breaks them off and collects. Inoculated logs usually produce for about four years total, with the greatest activity coming in the initial two. Aside from the shiitakes themselves, Winslow also sells inoculated shiitake logs upon request to the home grower.

“Out here amongst these stacks, if the mushrooms are releasing spores on a day that I’m working and the air is very, very calm,” says Uli, “it’s like fairy dust.”

A few shiitakes are particularly noteworthy, exhibiting striking patterns on their caps like crackled glazes. “These markings are the result of changes in the weather,” says Winslow. Particularly sought after, the scored lines are thought to intensify the umami taste of the mushrooms. In Japanese, the term umami roughly translates to savoriness and refers to the fifth recognizable taste, adding to the previous well-known four: sweet, sour, salty and bitter. Studied and now known as being caused by the naturally occurring amino acid glutamate, this pleasant savory flavor is found in seaweeds, anchovies, maturing tomatoes, aging cheese and more.

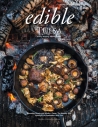

All three of the mushrooms Winslow cultivates should be cooked before eating. A quick sauté in butter or oil, with a little garlic, salt and pepper, and served hot or cooled atop a salad are what he prefers.

Marketing his mushrooms primarily at the local farmer’s markets, Winslow attends the year-round Orleans market as well as the seasonal Wellfleet and Truro markets. The Orleans market hopes to launch an online ordering system and remain open for outside pickups during the winter months at its location near The Chocolate Sparrow’s parking lot. Winslow also works with chefs upon request, supplying Ceraldi’s in Wellfleet and Black Fish in Truro. The public can check his outside stand located at the end of Holsbery Road in Truro for oysters and lion’s manes year-round and shiitakes from April to November.

Just before the Covid-19 outbreak, Winslow inaugurated his grant-funded visits to local schools detailing his experience with mushrooms. The program was temporarily halted due to the virus after a successful first presentation at the Eastham Elementary School. Feeling the experience would not translate well into Zoom sessions, he hopes to complete the series in the future, sharing in person with young students what he’s learned and demonstrating what a possible career in agriculture might look like.

Winslow’s persistent challenge is the neighborhood squirrels. Having his dog around helps, yet sometimes the squirrels merely eat the stems, leaving the caps. “They’ve damaged perhaps $1000 worth of product this year,” he smiles.

Can’t fault the squirrels, Uli. Cape Codders have good taste.

Uli’s Mushrooms

Farmers Markets — Seasonal: Truro, Wellfleet. Year-round: Orleans; Farm stand (year-round) — end of Holsbery Road, Truro 774-408-0279 (No calls please, texts only to check availability)

Instagram — ulismushrooms

Winslow’s recommendation for an inspiring read on mushrooms: Peter McCoy’s Radical Mycology.